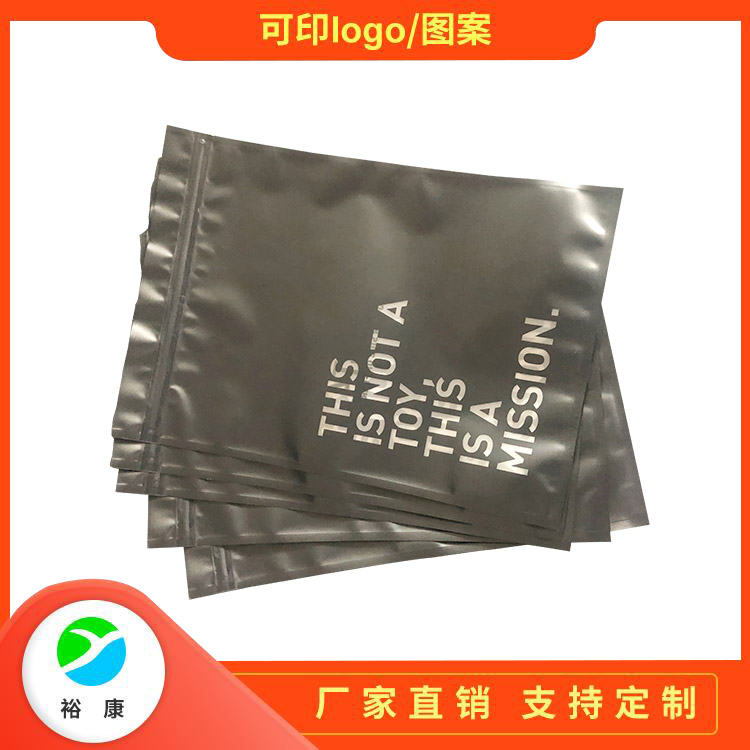

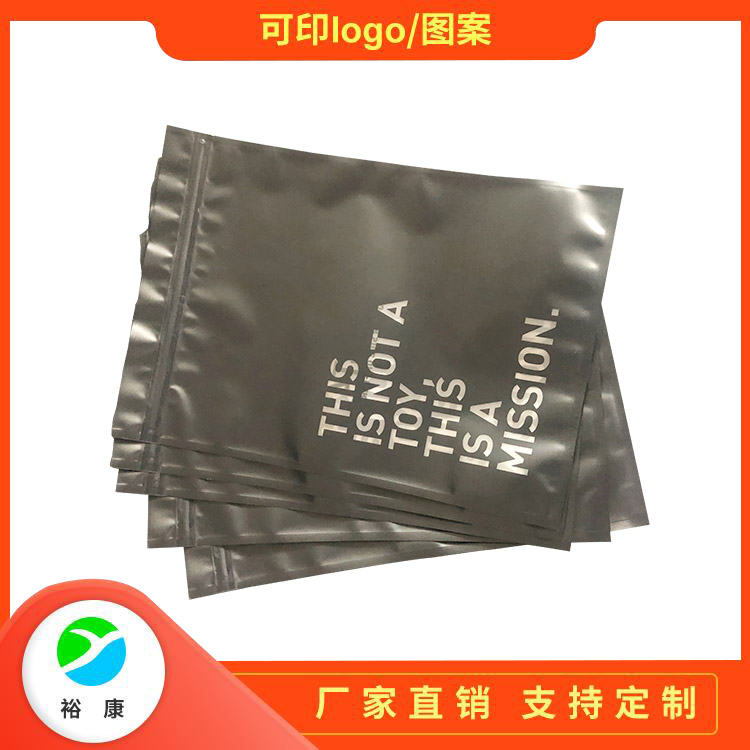

Yukang focuses on the production and sales of various plastic bags, zipper bags, bone bags, self-adhesive bags, composite bags, etc.

ChineseMobile site Wechat

Wechat

Yukang focuses on the production and sales of various plastic bags, zipper bags, bone bags, self-adhesive bags, composite bags, etc.

ChineseMobile site Wechat

Wechat

Service Hotline:+86-769-82813589

Contact:+86-137 9886 7028/Mr. Kang

Address: 2nd Floor, No. 20, Luxi Road, Xixi Village, Liaobu Town, Dongguan City